The JianXin Zhao’s Group Corporation (JZGC) is manufacturing systems and components for the international automotive industry utilizing 13 plants in China with future expansion plans in North America.

For commercial & passenger vehicles

Conventional engine mounts carry static and dynamic engine loads over the entire vehicle life and isolate vibrations in the low and high frequency ranges.

Bush bearings get more and more important by the usage in electric vehicles.

Tuned Mass Dampers reduce vibrations in many areas of the vehicles, from the tailgate to the steering wheel.

Torque struts are used to support the torque input of a power unit. They absorb torques from the drive train during acceleration or braking. Torque supports thus limit engine rolling motions.

Adaptive engine mounts offer an extension of classic hydraulic engine mounts by integrating a switching function. This switching function allows different adaptations to be made with regard to damping behavior.

The exhaust suspension fulfills several tasks. It reduces the transmission of structure-borne noise from the exhaust system to the body by means of targeted component tuning. At the same time, it reduces the movements of the exhaust system due to the component characteristics. High temperature resistance and durability are crucial.

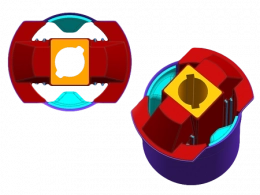

Dual compound technology offers a combination of the benefits of conventional and hydraulic bushings in one component, improving component performance.

The transmission mount is the most important connecting element between the transmission and the body of a vehicles. They support the transmission's own weight and limit driveline movement on the transmission side in the engine compartment. The bearing dampens vibrations and absorbs shocks caused by an uneven road surface.

Chassis bushings are used in many areas of the chassis and provide the connection between a wide variety of individual components.