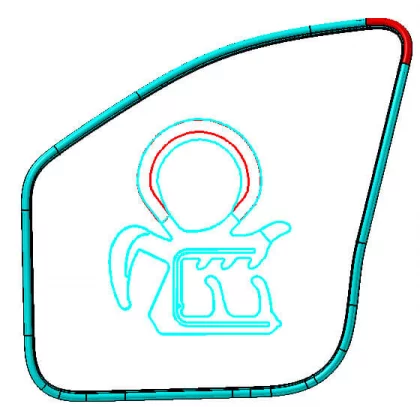

Process integration extrusion

Our bending processes are largely automated.

We extrude rubber and thermoplastics of choice on carriers made of metal or plastic. Up to 6 different materials can be extruded together to form a profile. Depending on the requirements, we apply decorative strips online or flock the profile. We have mastered the production of seals with variable wall thicknesses in order to reproduce complicated geometries on the vehicle.